It is important to undertake tasks with effectiveness and efficiency. However, the challenge comes up in the selection of the correct screw for the duty. There are important factors one should consider when selecting a lead screw for a given task. These important factors are;

a. Thrust

This is the force needed to move the screw and its load. There are two types of thrust; peak thrust – takes place during acceleration and lasts a short for a brief time. Continuous thrust is the second type of thrust which occurs when the system has attained maximum linear motion. To meet all the requirements of the system, the lead screw should have diameter equal to the amount of thrust required – the greater the thrust, the larger the screw diameter.

b. Speed

The linear motion’s speed in a particular task is very important. A typical type of speed for all lead screws is known as critical velocity. Critical velocity causes the linear screw to vibrate intensely and as a result affect their functionality. Product makers developed a ratio that shows the velocity of the lead screw based on input rotations-per-minute (rpm). Large lead screw have a lower potential rotations-per-minute thus they are used in tasks that require high speed to moderate the rpm.

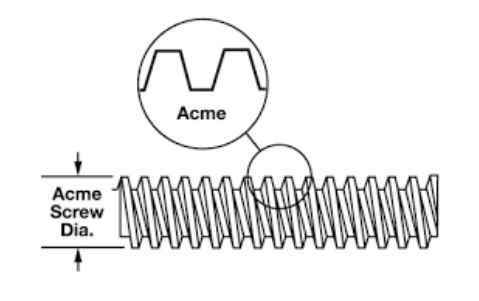

c. Repeatability

Repeatability is how the lead screw sustains tolerance after a series of movement. There is regular confusion between accuracy and repeatability. Some models of lead screws like acme screw and Helix lead have high repeatability. The repeatability causes them to be widely used.

d. Accuracy

Accuracy refers to the closeness of the lead screw’s movement of the load per tolerance level. Lead screws with high accuracy are applicable in tasks that require high accuracy. For such tasks, high accuracy lead screws are applied. The price of a lead screw is directly proportional to its accuracy levels. Lead screw functionality cannot be overlooked because of the high price tag. Further, mechanics still need and use these high accurateness lead screws regardless of their cost. In fact, they are the most common for many industrial applications.

e. Backlash

Backlash is the linear motion allowance that is between the nut and the screw when there is no turning. The impacts of a backlash are negative as they accelerate wearing out of parts and reduce the accuracy of the lead screw. However, lead screw designers are working to develop lead screws that do not have a backlash. One such significant development is the Helix AAB Axial Anti-Backlash lead screw.

f. Resolution

Contrary to the belief of many people that a proper combination between liner tool’s motor and the controller are the only way to control resolution, the correct type of lead screw is what affects the resolution. Small diameter lead screws have a higher resolution rate as contrasted to those with large diameters.

These six factors are the critical considerations when one is faced the challenge of choosing the correct lead screw for as particular task.

| < Prev | Next > |

|---|